Balitskiy started secondment at University of Novi Sad, Serbia H2020 MSCA RISE SALSETH project participant from MRC V. Researchers at Drexel University and the Materials Research Center in Ukraine have designed a system that can be used to make large quantities of the material while preserving its unique propertiesĬANBIOSE project participant from MRC completed secondment visit to partner organization Vilnius University, Lithuania, on February-March 2020 due to CANBIOSE projectĬANBIOSE project participant from MRC performed secondment visit to project partner organization Vilnius University, Lithuania, on February 24 - March 14 2020. Scalable Production System for the Promising, 2D Nanomaterials MXenesįor one of the most promising new types of 2D nanomaterials, MXenes, that’s no longer a problem. Training of early-staged researchers involved in CanBioSe research works on nanomaterials processing and scientific seminar on Advances in nanomaterials research for biomedical applications, were held with invited experts. H2020 MSCA RISE CanBioSe project activities - EsR/ER training and scientific seminar held in MRC, Kyiv, Ukraine, July 30-August 01, 2020 This article is also Highly Cited in Web of Science (top 1% of all papers in the field).

MRC and Drexel collaborative article on Scalable MXene synthesis is listed among the most accessed in Advanced Engineering Materials journal for the whole year

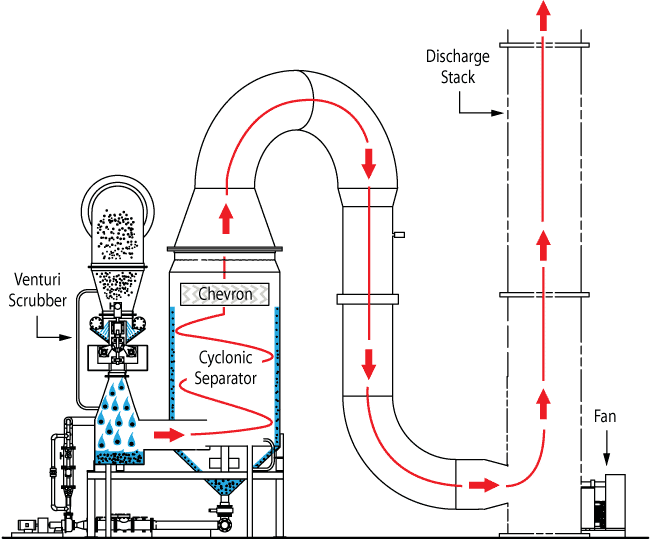

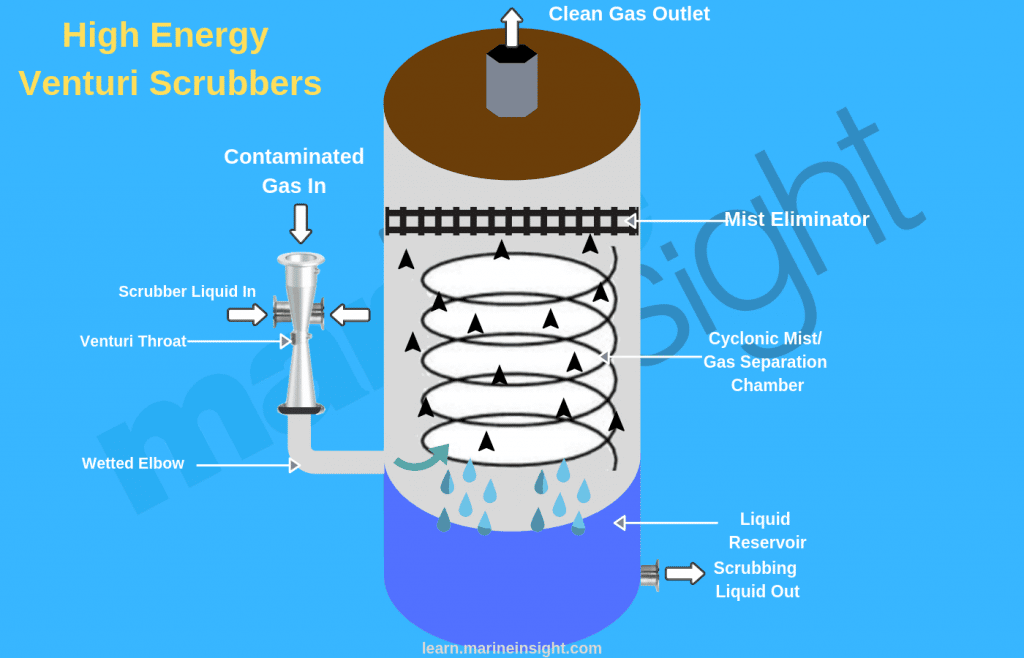

The discovery is a key development for efforts to weave technological capabilities into clothing and accessories. Researchers at Drexel University’s College of Engineering have reported that MXene coated fabric is highly effective for blocking electromagnetic waves and potentially harmful radiation. MXene Coating Could Prevent Electromagnetic Interference in Wearable Devices “Our fundamental study of titanium carbide MXene supported by NSF showed that MXene is biocompatible, able of adsorbing a variety of small molecules, and holds a lot of promise in medical applications, so it is exciting to see it applied for improving and really changing dialysis - an area of need in health care that can help millions of people,” said Yury Gogotsi, PhD, Distinguished University and Bach professor in Drexel’s College of Engineering, who is a world leader in developing and studying MXenes. For more information or to speak with one of our qualified experts, contact us today.Drexel's MXene Filter Materials will be used for Wearable Artificial Kidney Technology Honiron Manufacturing is an industry-leading designer and manufacturer of pressure vessels. While dry industrial scrubbers generally aren’t capable of achieving the same level of pollutant removal as wet scrubbers, they are better suited for certain applications, particularly in facilities that do not have infrastructure in place to properly handle produced wastewater. Dry industrial scrubber systems routinely include a material/substance that facilitates the removal of the reaction material after it is bound to the contaminant. Once again, surface area is critical, so gas is passed through a sorbent “dust” to maximize binding. They are primarily implemented for removal of acid from gas. Instead, dry industrial scrubbers utilize a dry reaction material known as “sorbent”, such as alkaline slurry. In contrast, and as the name suggests, dry industrial scrubbers aim to remove pollutants from exhaust gases without the use of liquid. Because of high moisture levels, wet scrubbers often produce waste water and highly visible clouds of steam discharge from chimneys, which may or may not require additional waste removal measures depending on the application. The degree to which liquid is mixed with the incoming gas stream can also impact its operation. Surface area of the liquid has a significant impact on the overall effectiveness of wet scrubbers. Liquids may be positive or negatively charged and differ in chemical composition to ensure binding and removal of the contaminants being expelled. The technique involves passing contaminated gas through a liquid designed to remove pollutants. In fact, wet scrubbing processes generally are capable of removing more than 99% of air particulate matter and capturing aerosols less than 3 µm.

Wet scrubbers are one of the most versatile and cost effective pollution control technologies. Wet and dry industrial scrubbers are two of the most effective pollution removal technologies. Because of this, facilities are required to take measures to remove pollutants before gases can be released into the atmosphere. Exhaust gases produced from industrial processes often contain substances that are harmful to the environment.

0 kommentar(er)

0 kommentar(er)